Dependable Services…

Over the years, Winston has grown to become an aerospace quality job shop that specializes in serving other job shops and manufacturers. Our customers range from one-man machine shops to large tier 1 automotive suppliers and major aerospace primes. We recognize that each and every customer deserves and requires specialized handling and care in the processing of their parts.

Our goal has and always will be to be the stress-free portion of your supply chain. We offer a wide-range of heat treatment solutions to provide the various services that you need to the highest degree of quality in the shortest lead time possible.

Where others cut corners or delay loads for maximum profitability, we instead expedite special runs to make sure you or your customer on break down gets the part they are depending on as soon as possible. Never hesitate to call us with your urgent need!

Our services include:

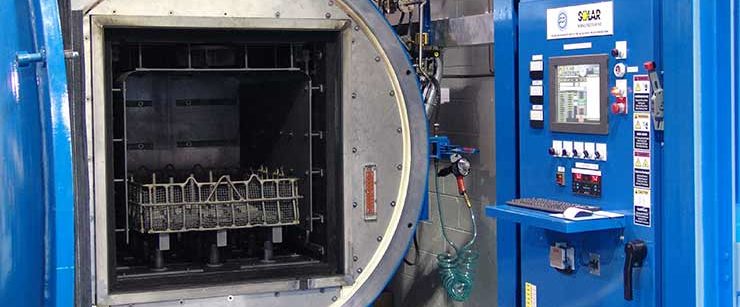

Our vacuum heat treating services include:

- Hardening

- Annealing

- Solution Heat Treatment

- Precipitation/Age Hardening

- Stress Relieving

- Normalizing

Our capabilities

- Up to 36” x 36” x 48”

- Depending on final dimensions, we can accommodate parts up to 50-55” in length

- Up to 3,000 pounds per heat lot

- Up to 10 bar nitrogen quench and up to a 4 bar argon quench

- Furnace controls/pyrometry calibrated to aerospace (AMS 2750) approval

- Custom-recipe development for repeatable part numbers

- Digital storage of furnace records for traceability by customer, PO number, part number, material, etc.

Our atmosphere heat treating services include:

- Neutral Hardening/Quench & Temper

- Carburizing/Case Hardening

- Carbonitriding

Our capabilities

- Up to 36” x 36” x 48”

- Depending on final dimensions, we can accommodate parts up to 50-55” in length

- Up to 4,000 pounds per heat lot

- Furnace controls/pyrometry calibrated to aerospace (AMS 2750) approval

- Custom-recipe development for repeatable part numbers

- Digital storage of furnace records for traceability by customer, PO number, part number, material, etc.

Our gas nitriding services include:

- Traditional Pit Nitriding

- State of the art Vacuum Nitriding

Our capabilities

- Up to 28” x 34” x 48”

- Up to 2,500 pounds per heat lot

- Precise controls for both assuring case depths and minimizing white layer

- Furnace controls/pyrometry calibrated to aerospace (AMS 2750) approval

- Custom-recipe development for repeatable part numbers

- Digital storage of furnace records for traceability by customer, PO number, part number, material, etc.

Cryogenics Treatments

Our cryogenic treatment services include:

- Deep freeze cryogenics up to -320°F

Our capabilities

- Up to 36” x 36” x 48”

- Up to 3,000 pounds per heat lot

- Furnace controls/pyrometry calibrated to aerospace (AMS 2750) approval

- Custom-recipe development for repeatable part numbers

- Digital storage of furnace records for traceability by customer, PO number, part number, material, etc.

Value Added Services

Flame/Induction Hardening

Selective hardening or softening of areas like threads, punch heads, gear teeth, etc.

Straightening

Typically, we can guarantee parts to remain flat and straight within .005” TIR or better. Methods of straightening include pressing, cold-working or hot working with a torch.

Glass Bead Blasting

Up to approximately 24-30” square.

Free Pick-Up and Delivery Service

We offer our customers free pick-up and delivery with heat treatment of parts within a roughly 75-mile radius from our facility. Call to confirm and arrange.